Electric mobility

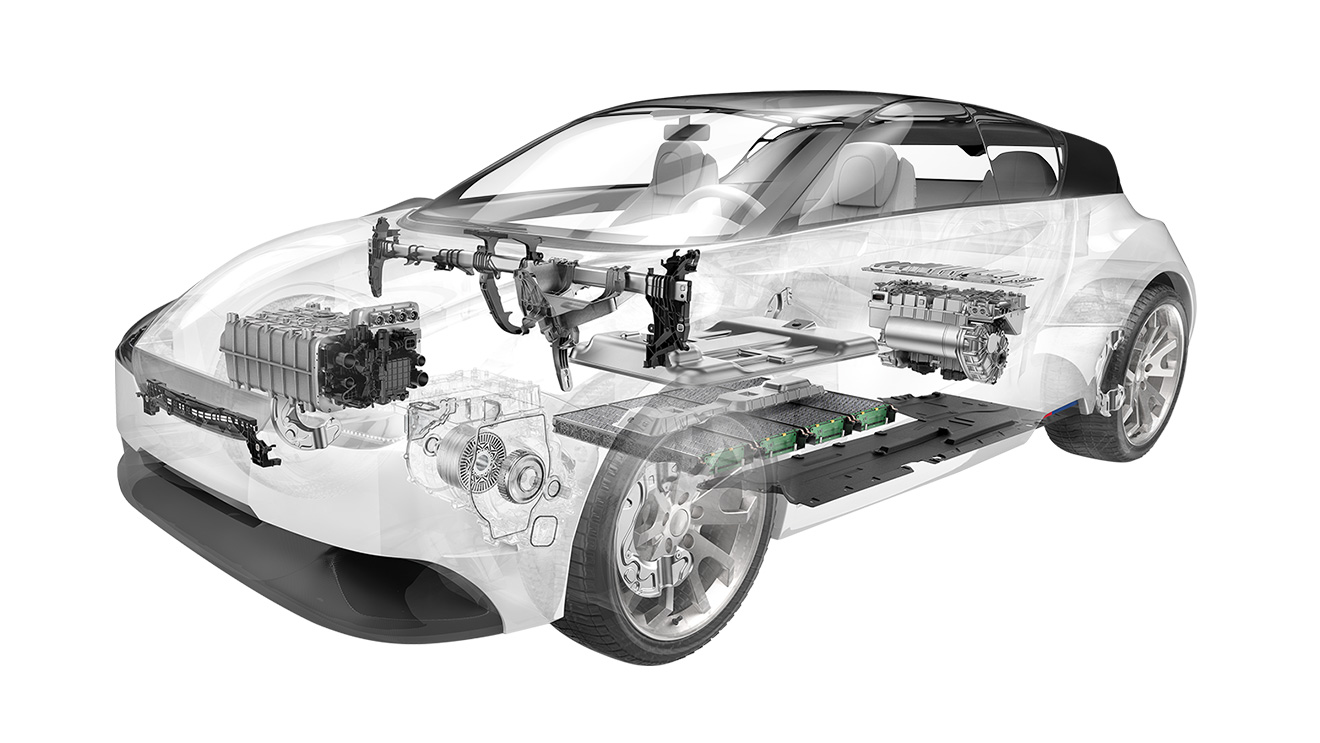

Components for electric drive units (EDUs)

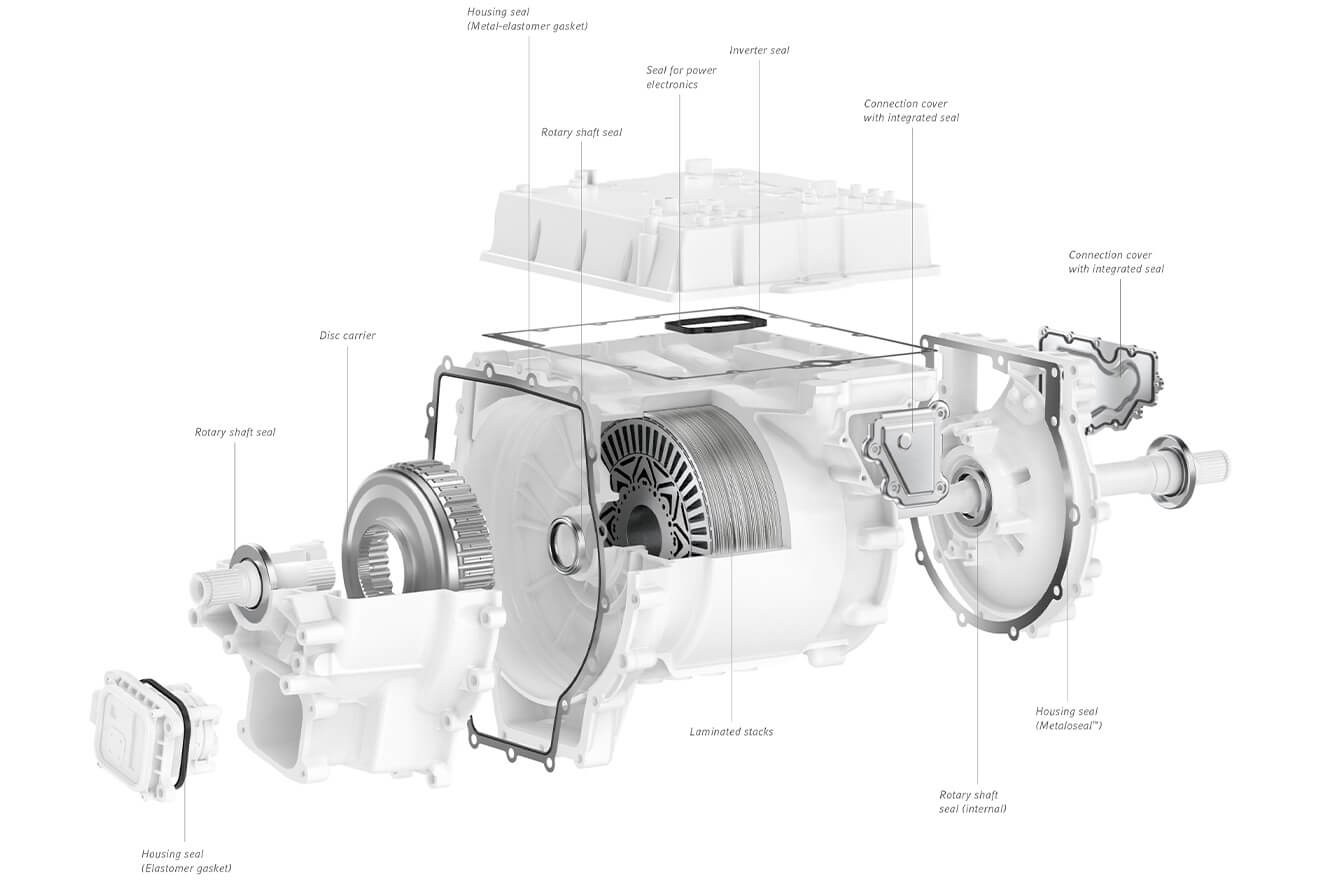

A wide range of ElringKlinger components relating to e-motors, transmissions and inverters can be used in an electric drive unit. The design and materials of all our product solutions are tailored precisely to the relevant requirements – for maximum design freedom and functional reliability.

MetaloBond™ rotor/stator laminated stacks

- Full bonding of the layers ensures optimum sealing function in order to implement directly cooled electric machine concepts

- Improved strength and NVH performance

- Thin sheets possible for even more efficient electric machine operation

- In-house development of adhesive enables maximum flexibility in material selection

- Less pressing strokes required to achieve the stack height due to innovative manufacturing processes

Balancing discs

- Punched/formed part with weight and cost-optimized design

- High precision production process ensures tight tolerances and eliminates secondary processes

- Maximum flexibility with regard to material selection

- Material thicknesses up to 10 mm possible

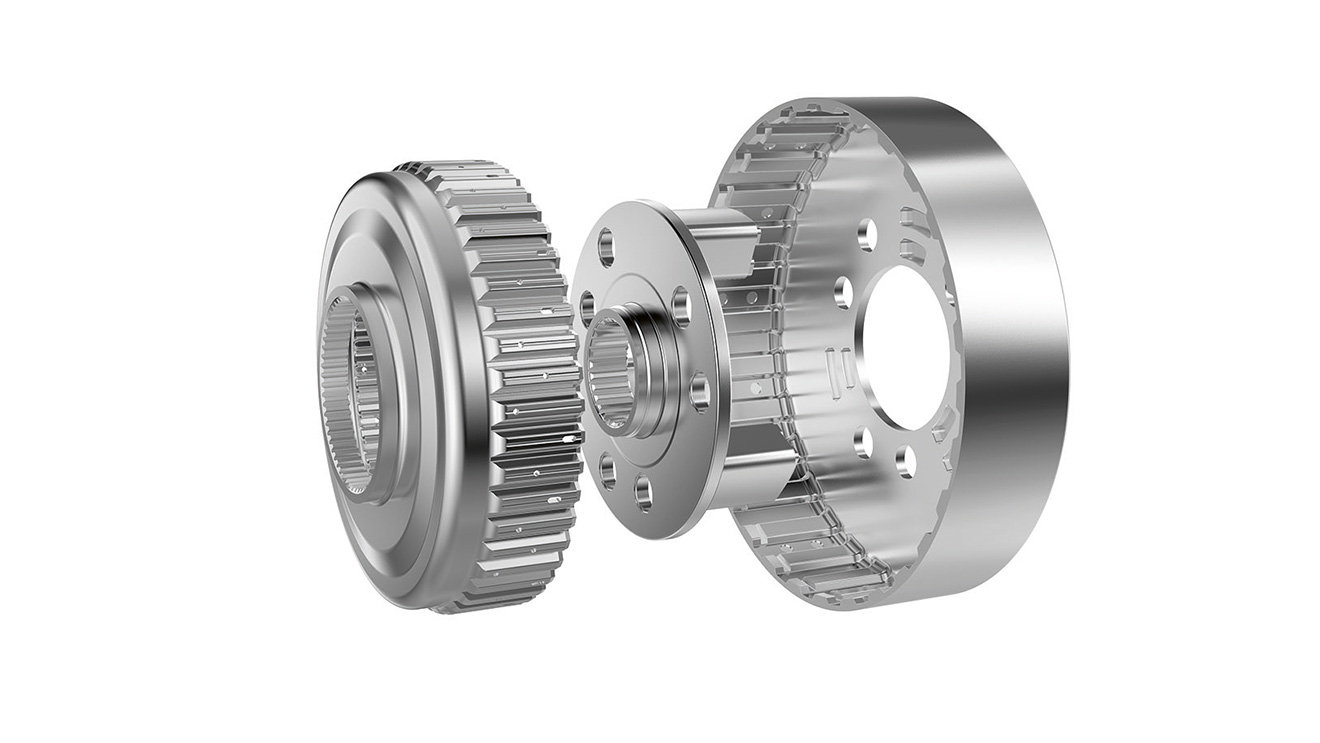

Planetary carriers

- New method: Planetary gears integrated into shaped sheet metal part

- Weight and cost savings

- High torques and speeds

- Longer service life of the gear wheels

Disc carriers

- High strength for transmission of higher torques

- Maximum precision and functional reliability

Weight savings of up to 50 percent compared to standard commercially available solutions

Differential housing

- Formed sheet metal design

- Significant weight reduction in applications with high torque

Engine and unit mounts

- Made of glass-fiber reinforced thermoplastics

- Multifunctional

- Weight and cost reduction

- Improved NVH characteristics

- Low thermal conductivity

- High dimensional accuracy

- High process stability and repeatability

Plastic modules

- e.g. inverter housing, resolver cover, media distributor modules

- With integrated EMC shielding

- Weight and cost reduction

- Functions can be integrated

- Optimized NVH properties

- Low thermal conductivity

- High process stability and repeatability

ElroForm™ metallic housing covers/covers

- e.g. for inverters, HV shielding and charging unit

- Ideally suited for replacing die-cast partsIdeally suited for replacing die-cast parts

- One or more parts

- Functions can be integrated

- For high crash safety requirements

Elastomer/metal elastomer sealing systems

- e.g. inverter seals, stator housing seals, transmission housing seals

- For components subject to high loads

- Electrical conductivity for EMC requirements

- Elastomer materials developed in-house by ElringKlinger

- Reliable sealing even with low sealing pressures

- Sealing of T-joints

- Equalization of high component tolerances

- Three-dimensional shaping

- Reduction of screw force and number of screws

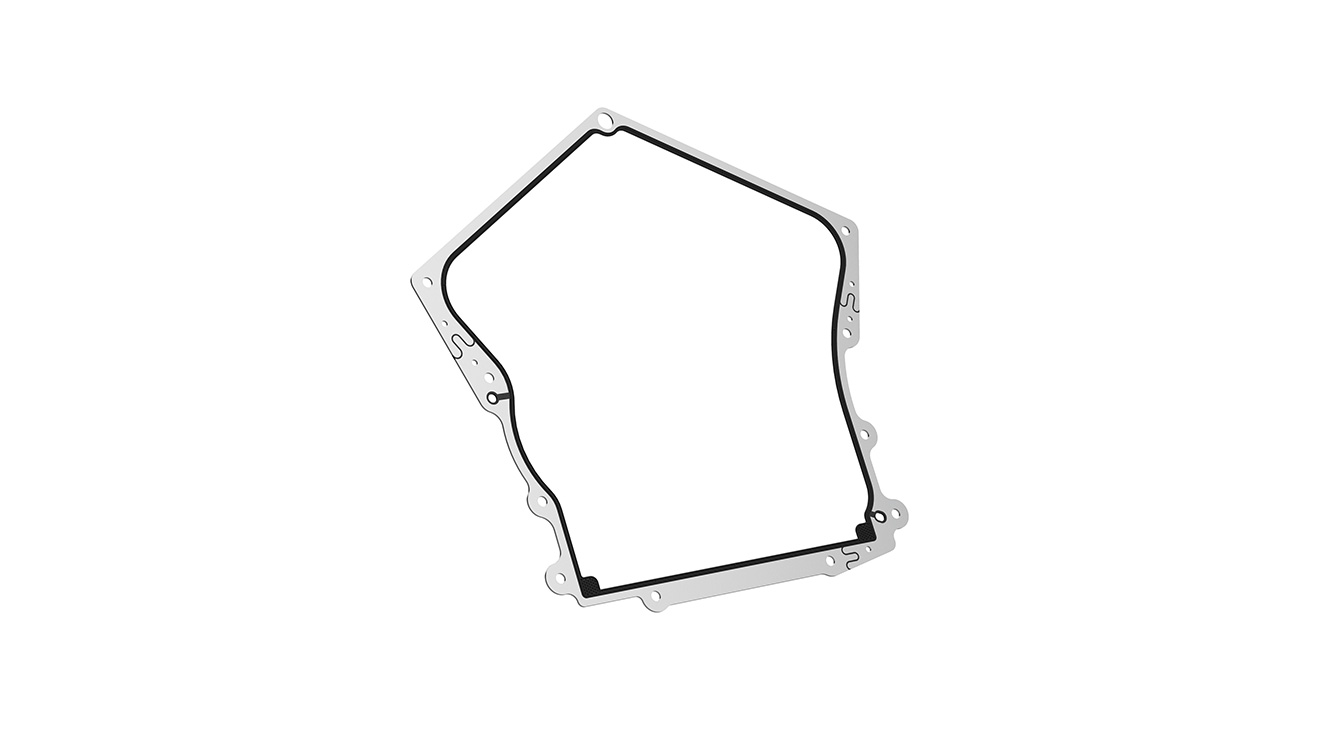

MetaloSeal™ metal bead gaskets

- e.g. stator housing seals, transmission housing seals, inverter seals

- Thanks to numerous combination options for metals and elastomers, can be adapted precisely to the relevant requirements

- Functional coatings, e.g. conductive coating for EMC shielding

- Installed in direct line of force

- Positioning plates and retaining clips for quick and reliable installation, vertical and upside down

- High media, temperature and pressure resistance

TopSeal™ deep-drawn covers

- e.g. inverter cover, service cover, cover of electrical components and connection covers

- Topographic support of the integrated seal using embossed stoppers

- Improved corrosion resistance

- With functional integration, e.g. screws, ventilation elements

Best possible screening against electromagnetic radiation

Made of high-performance plastics

- ElroSeal™ B/E/EM/SD shaft sealing rings and piston rings for fast-rotating shafts

- ElroSeal™ G/EG shaft sealing rings for bearing protection

- Venting elements for brush space

- Dynamic sealing at extreme rotational speeds, can also be combined with reliable discharge for component protection

Expertise to support transformation: ElringKlinger supplies numerous components for electric drives (EDUs), including metal-elastomer and Metaloseal™ seals, as well as rotary shaft seals and housing covers.

Downloads

Product overview

Electromobility

Events

Company