The force of change

ElringKlinger looks to a future that could not be more diverse. A “transparent” drive unit with dynamic precision parts and various sealing solutions for electric-powered vehicles shows how decades of experience in the manufacturing of conventional automotive components help when it comes to developing innovative products for next-generation technologies.

Thanks to the company's proven material and tooling expertise, ElringKlinger products can withstand extremely high mechanical loads and speeds – and always work efficiently andy reliably.

Early one morning in August 1888, Bertha Benz set off on an adventure that would change people’s lives. At the wheel of the Benz “patent motor car” model 3, she undertook the first long-distance road trip in automotive history, from Mannheim to Pforzheim and back again. By driving these 180 kilometers, she proved for the first time that the automobile had a big future ahead of it. Just like back then in 1888, society is today facing a fundamental change in the very nature of mobility. Whereas then, the shift was from coach to automobile, now it is completely new mobility concepts and technologies that are set to permanently change what is a key industry in many countries. The example of Bertha Benz shows that believing in one’s own innovations as well as courage and staying power play an important role in achieving commercial success.

The force of change is also what is driving ElringKlinger, as the current transformation in the automobile industry is breaking up established processes, structures, and systems and calls for strategic realignment. This is a key challenge that the ElringKlinger Group has been helping to resolve for more than two decades, as it is the company’s declared objective to steer its technological expertise successfully into the future.

The development of the automobile has been remarkable. Whereas a good 130 years ago, Bertha Benz drove her combustion-engine-powered car noisily over stony tracks at around 20 km/h, modern electric cars can accelerate from 0 to 100 km/h in just 4 seconds and reach top speeds of around 200 km/h with hardly any noise.

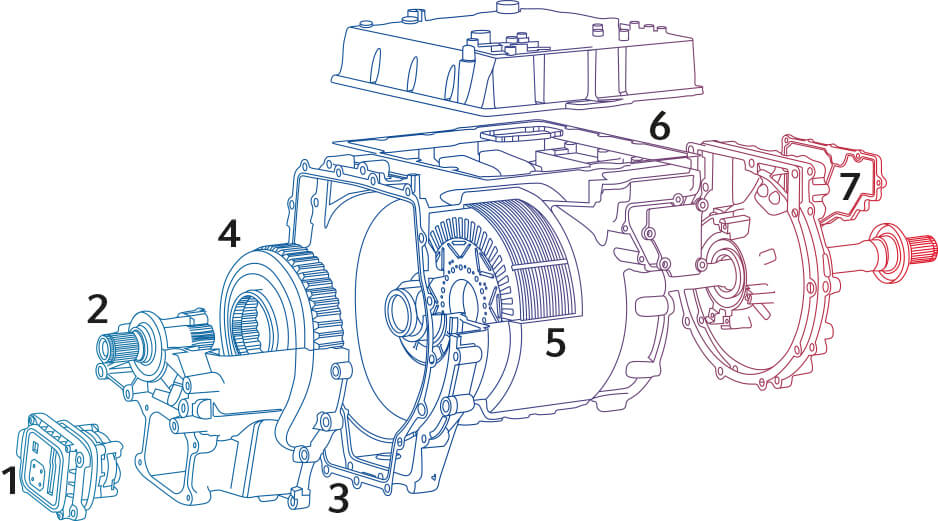

Modern electric cars achieve this enormous power needed to accelerate the vehicle using an integrated electric drive unit in which electric motor, transmission, and drive shaft are combined into one unit. The electric drive unit contains both the power electronics and the overall drive control system and converts the direct current of the high-performance battery into three-phase AC power. The electric motor in turn converts this electrical energy into mechanical energy so that the transmission can transfer the torque to the wheels.

The products installed in electric cars must meet stringent requirements, because both speed and torque are many times higher than the respective requirements for a combustion engine. In this area, ElringKlinger is leveraging its extensive experience in punching, embossing, forming, and coating to transfer knowledge from the combustion engine environment to the new drive concepts. As regards the electric drive unit, for example, this knowledge is being applied systematically to develop and manufacture dynamic precision parts and customized sealing solutions.

1. A pressure-boundary flanged connection has to be created for elastomer sealing systems in the case of load-carrying joints, e. g., by means of a groove in the component. Precisely matched profile geometries ensure maximum functionality at extremely low sealing pressures.

2. Thanks to the use of fluoropolymer sealing technology, rotary shaft seals withstand high speeds of revolution, alternating directions of rotation, and high pressures and temperatures.

3. Metal-elastomer seals are particularly suitable for sealing highly stressed components. Thanks to modern injection molding technologies, customer-specific elastomers can be bonded to a carrier material in metal or plastic.

4. Disc carriers are made of metal and are manufactured in just a few process steps in special dies using high-precision forming technology.

5. In the electric motor, the rotor and stator ensure efficient operation thanks to their high packing density. A specially developed three-stage manufacturing process reduces the punching strokes while using thinner sheets to achieve the necessary package height.

6. Metaloseal gaskets are based on elastomer-coated and uncoated metal carrier materials. Different metals can be combined with different types of elastomer and tailored exactly to the respective requirements.

7. Metal covers with an integrated seal cover and seal off the housing and passages in the electric drive unit. They can be used as a service cover, a cover for electronic parts, or a cover plate in engine and transmission.

As a development partner, ElringKlinger applies its expertise in precision punching and forming to the development of dynamic precision-formed and punched parts, the aim being to achieve performance increases in the vehicle through intelligent product design, while using the minimum of material possible and optimized manufacturing processes. A good example of this is the new stator and rotor concept. The stator and rotor represent the heart of every electric motor and are what enable an electric vehicle to be driven with high speeds of revolution and torques in the first place. To increase the performance of the electric motor and the cost effectiveness of the product, the development engineers have optimized no less than three key parameters: material thicknesses, joining technologies, and manufacturing process. The resulting benefits are a higher packing density, cost-effective machining of sheet thicknesses less than 0.25 mm, and the option of direct cooling of stators, which until now were integrated into a separate stator housing.

The electric drive unit also brings new challenges related to sealing. Because unlike combustion engines, where due to high pressures, the sealing systems guarantee a reliable seal of the various media – oil, coolants, fuels, and fuel gases – to the outside and between one another, the focus with electric drive units is on protecting the technologically sensitive areas from an ingress of media from the outside. So the direction is reversed. Therefore, the new sealing systems must meet special IP protection classes to prevent any media from getting into the interior of the sensitive system. This is precisely why the newly developed sealing systems differ from the previous systems used in combustion engine vehicles, in respect of both the composition of the elastomers used and the product design.

The electric drive unit pictured below shows that thanks to its abilities as a developer the ElringKlinger Group is already providingthe answers to the questions of the future and mastering challenges in its capacity as a driver of innovation. Due to the continuing transformation of its product range, ElringKlinger made more changes to its organizational structure in 2020, by combining the Cylinder-head Gaskets and Specialty Gaskets business units into the new Metal Sealing Systems & Drivetrain Components business unit. As part of the same process, the Group repositioned the new business unit to combine metal sealing systems and precision punched and formed components for all kinds of drive systems with one another.