Battery technology. Electromobility is moving the world.

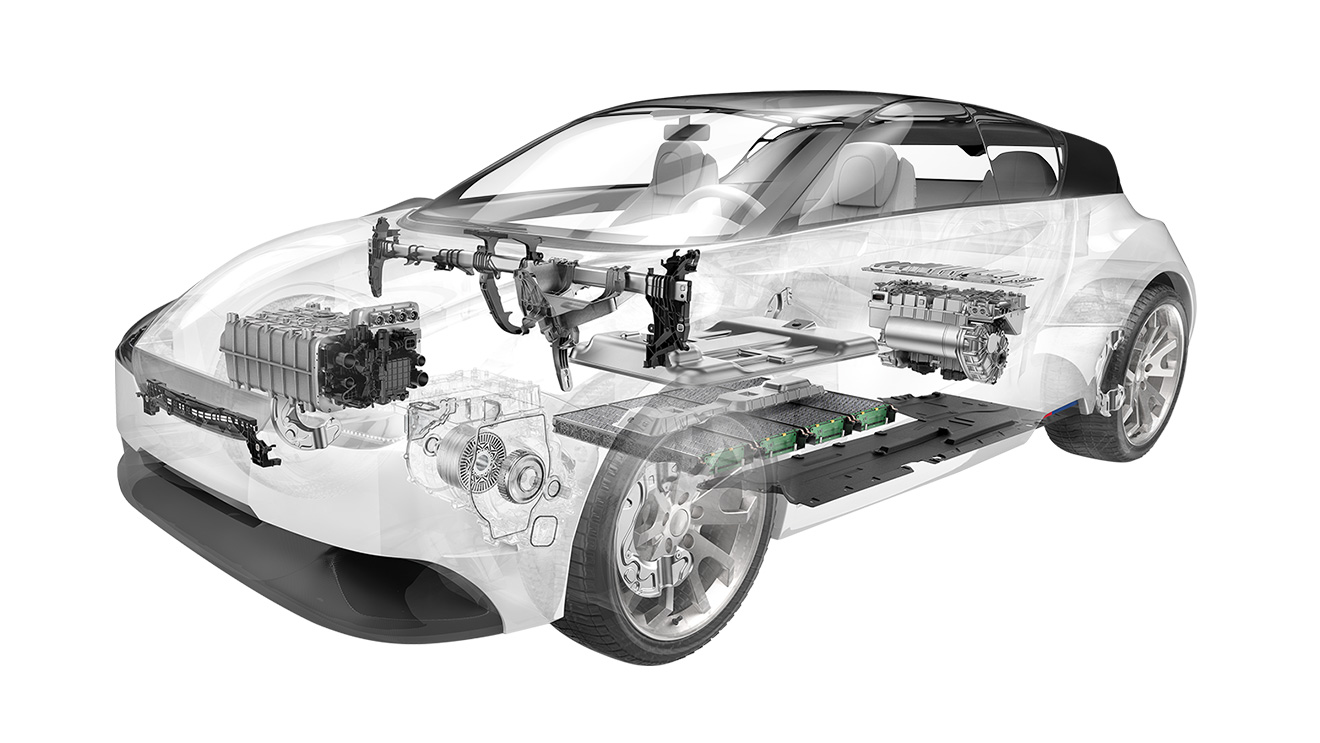

An efficient energy storage device is a key piece of technology for sustainable electric vehicles. ElringKlinger offers complete lithium-ion battery storage systems and modules for drives and auxiliary power units, as well as various individual components. Intelligent, flexible, absolutely reliable, and field-tested. The major advantage for our customers: ElringKlinger offers development and prototype construction to testing and series production from a single source. And this isn't a recent development: We have been a series supplier in battery technology for more than 10 years.

Products in the field of battery technology. Future-proof solutions in series production.

One of ElringKlinger's core areas of expertise is combining a variety of different components reliably into a single assembly. This is a key advantage, in the field of battery technology in particular. We are a development partner and supplier of both individual components and complete systems.

Good to know: Our product areas for lightweight construction/elastomer technology, sealing technology, drive components as well as metal forming and assembly technology, also provide tailored solutions for electric vehicles, such as battery housings and covers, components for thermal propagation protection, stamp packages, a wide range of sealing systems and underbody shielding.

Development and testing. Combined expertise.

Holistic thinking creates intelligent solutions at the highest technological level. We bundle our research and development activities in all aspects of battery technology at our sites in Dettingen/Erms, Neuffen and Thale, thereby driving forward innovations. All testing and safety equipment is combined here under one roof, such as cell tests, module and system tests or component protection, in order to test the products comprehensively. We master all processes, so we can offer our customers the optimum conditions for breaking new ground and achieving goals faster - including for small series and prototypes.

E-Mobility: Prototype construction and series production.

When it comes to innovative production concepts, we have always placed great importance on our in-house process development and the associated development of expertise. By closely integrating development, prototype construction, and series production, an optimal level of quality can be achieved immediately on start of production.

ElringKlinger creates samples and small series in the field of battery technology in a short time and top quality in in-house, series-oriented prototype construction. Resources are available there for all production processes, which are also used in series production, such as ultrasonic or laser welding. In this way, we achieve a consistency across all processes, from prototype to series production, with only the degree of automation being adapted. Complete 100% traceability can be ensured as early as prototype construction, as well as in subsequent series production.